Reconditioned Atco and Brilliant Mower operation and settings

If you have any problems with a mower that I have supplied, please contact Shane Cox of Ready Set Mow. His contact details are on the mower. He usually responds quickly and often uses a video call to resolve issues, most can be resolved with a spanner or screwdriver. He is usually available on working days 8am to 4pm. At weekends, contact Duncan.

Shane builds these mowers and has in-depth engineering knowledge and experience. He and I offer a personal service. We are easy to contact and almost always available.

The mowers are of Atco original manufacture and can be likened to a Land Rovers. Just about everything can be adjusted with a spanner or screwdriver. They last a very long time. I bought mine about 35 years ago. It has been upgraded by Shane to the Brilliant mower spec but hasn't been re-painted. It has the 14 blade cylinder and a Lifan electric start engine and cuts beautifully. My lawn is cut to 5mm through the playing season giving a lawn speed of 11 to 12 Plummers except in wet weather when it drops to about 10.

Shane builds these mowers and has in-depth engineering knowledge and experience. He and I offer a personal service. We are easy to contact and almost always available.

The mowers are of Atco original manufacture and can be likened to a Land Rovers. Just about everything can be adjusted with a spanner or screwdriver. They last a very long time. I bought mine about 35 years ago. It has been upgraded by Shane to the Brilliant mower spec but hasn't been re-painted. It has the 14 blade cylinder and a Lifan electric start engine and cuts beautifully. My lawn is cut to 5mm through the playing season giving a lawn speed of 11 to 12 Plummers except in wet weather when it drops to about 10.

I recommend that you always call Shane as a first port of call rather than a local engineer. He is easy to contact and can usually sort out problems on the phone.

Starting the mower

Turn on fuel (I use standard unleaded E10 fuel and have had no problems)

Open Throttle to start. I usually leave the throttle set at a reasonable walking pace and I don't touch it before, during, or after mowing.

Pull start - Apply choke and pull the chord. When running, ease the choke back.

Electric start. Apply choke and turn key. When running, ease the choke back. Don't forget to switch off when you have finished mowing otherwise the battery will lose charge.

Open Throttle to start. I usually leave the throttle set at a reasonable walking pace and I don't touch it before, during, or after mowing.

Pull start - Apply choke and pull the chord. When running, ease the choke back.

Electric start. Apply choke and turn key. When running, ease the choke back. Don't forget to switch off when you have finished mowing otherwise the battery will lose charge.

Mowing

WARNING

The chain guard is, of necessity, close to the ground. This means that when mowing the edge of a lawn next to long grass, the chain guard can catch. For this reason edging should always be done with the right hand side of the mower.

The chain guard is, of necessity, close to the ground. This means that when mowing the edge of a lawn next to long grass, the chain guard can catch. For this reason edging should always be done with the right hand side of the mower.

To engage cylinder

Pull the engaging lever upwards to release and slide in towards the machine. To disengage, pull the lever outwards and press down to retain.

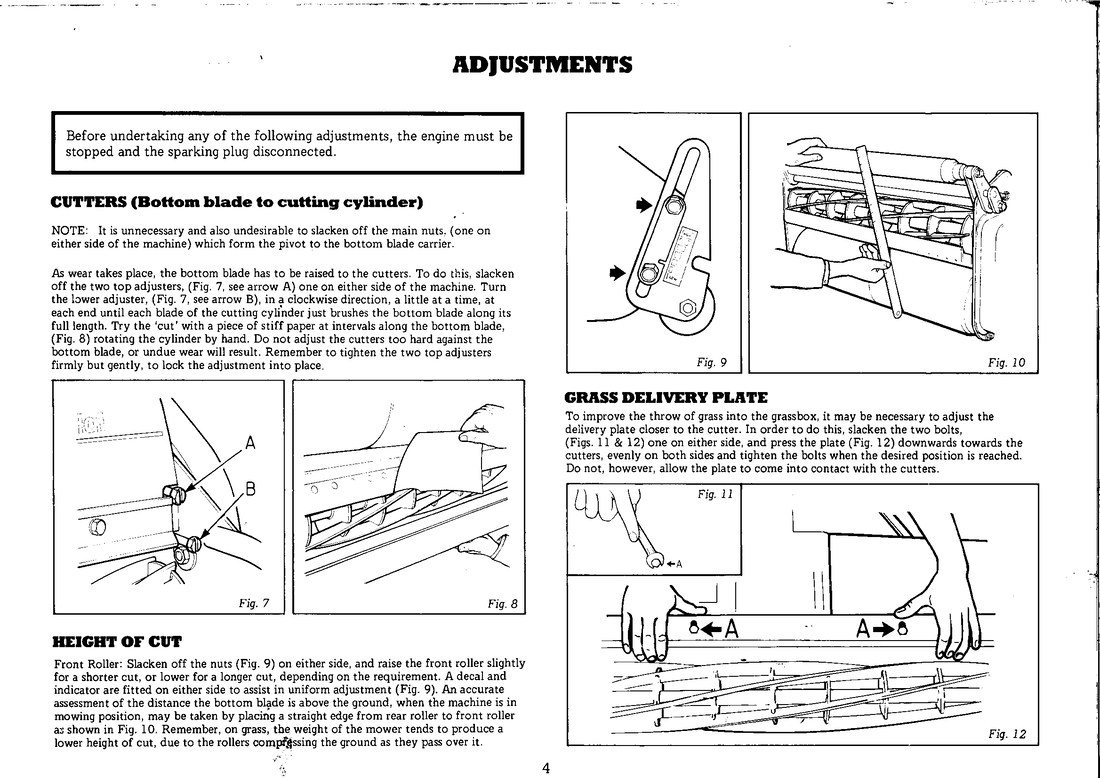

Setting Height of cut

A setting bar, spanner and mallet are provided with the machines that I supply. Set the underside of the bolt head on the setting bar to the desired height of cut. Adjust the front roller so that the bolt head snugly clips over the bedknife. See the video below.

WARNING Don't tip the mower more than about 35 degrees when setting the bedknife. If tipped too far, engine oil can oil can seep into the cylinder. Wedging the machine so that it is resting on the trailing seat brackets is the easiest method.

WARNING Don't tip the mower more than about 35 degrees when setting the bedknife. If tipped too far, engine oil can oil can seep into the cylinder. Wedging the machine so that it is resting on the trailing seat brackets is the easiest method.

Setting the bedknife "on cut".

|

After a lot of use, a mower will not cut the grass cleanly and you will notice that some blades of grass are bruised but not cut. This is a sign that the bedknife needs to be adjusted. The bed knife adjusting bolts are shown in the photo above. To move the bed knife nearer the cutting cylinder, use the screwdriver supplied to loosen the top bolt very slightly, an eighth of an inch turn may be enough and tighten the bottom bolt by the same amount. Do this on each side. If the cylinder binds on the blade, back off a fraction until it rotates freely again. The idea is to get the bedknife as close as possible to the cylinder. This is quick and easy to do when mowing. You don't have to remove the trailing seat or tip up the mower. The textbook method is different, more time consuming and doesn't work for me. Nevertheless, see the video below and you will get a better idea of how it works.

|

|

Video

This video explains the setting very well. The star of the show is Leigh Bowers who left Allett a few years ago. He used to train my customers when I supplied Alletts. I don't use his method of setting (on cut) with paper. I prefer the method described above.The machine he is using for the demo is similar to Atco and Brilliant mowers. youtu.be/b79Ur6UrMM4

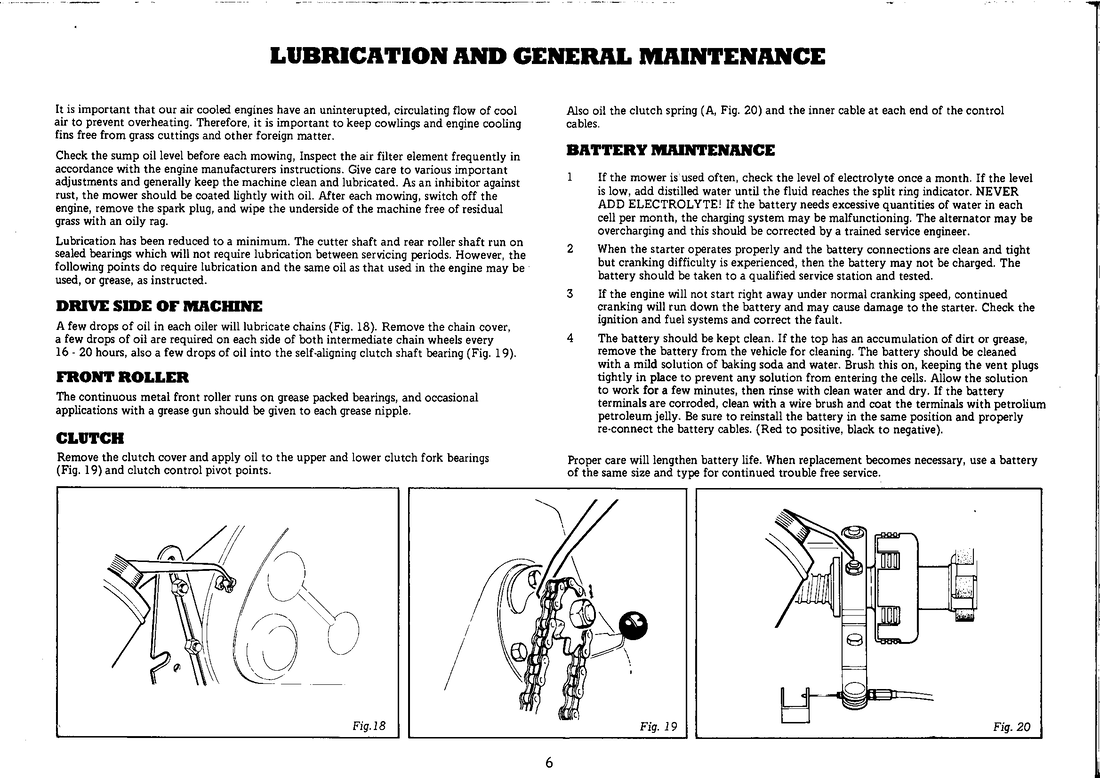

Drive chains - lubricate and check tension.

|

The drive chains are accessible by removing the side cover on ATCO and Brilliant mowers. Lubricate every two weeks and check the tightness of the chains. I use Motip Industrial Chain Grease which comes in a spray can. Unlike normal grease, it is designed to cling to moving chains and works really well. I check my chains every fortnight but haven't had to reapply Motip for ages.

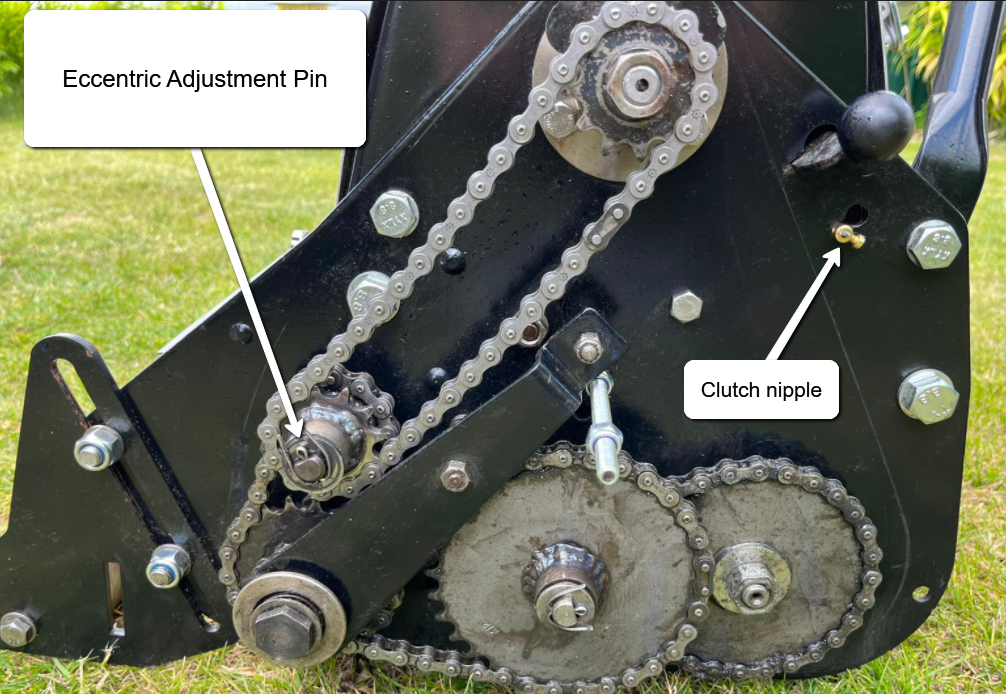

To adjust the chain tension, slacken the intermediate shaft nut ( shown below), using a 19mm spanner and rotate the eccentric pin in the sideplate. (To get at this nut you will have to remove the lower bedknife bolt.) The intermediate shaft nut and pin can also be adjusted backwards and forwards. Lock the shaft nut tightly after adjustment and replace the lower bedknife bolt. |

It should be easy to pull the mower backwards. If the roller jams or resists, it is a sign that a chain is too tight OR the clutch needs to be adjusted.

First try squeezing the clutch lever, if the mower moves freely again, you know that the clutch cable needs adjusting. If not, the problem is most likely to be that one of the chains it too tight. In this case, adjust to chains to prevent a link breaking.

Replacing a broken chain.

Chain can be purchased online from Beltingonline.com. You will need a 3/8" to 5/8" chain breaker/rivet extractor which they can also supply here

First try squeezing the clutch lever, if the mower moves freely again, you know that the clutch cable needs adjusting. If not, the problem is most likely to be that one of the chains it too tight. In this case, adjust to chains to prevent a link breaking.

Replacing a broken chain.

Chain can be purchased online from Beltingonline.com. You will need a 3/8" to 5/8" chain breaker/rivet extractor which they can also supply here

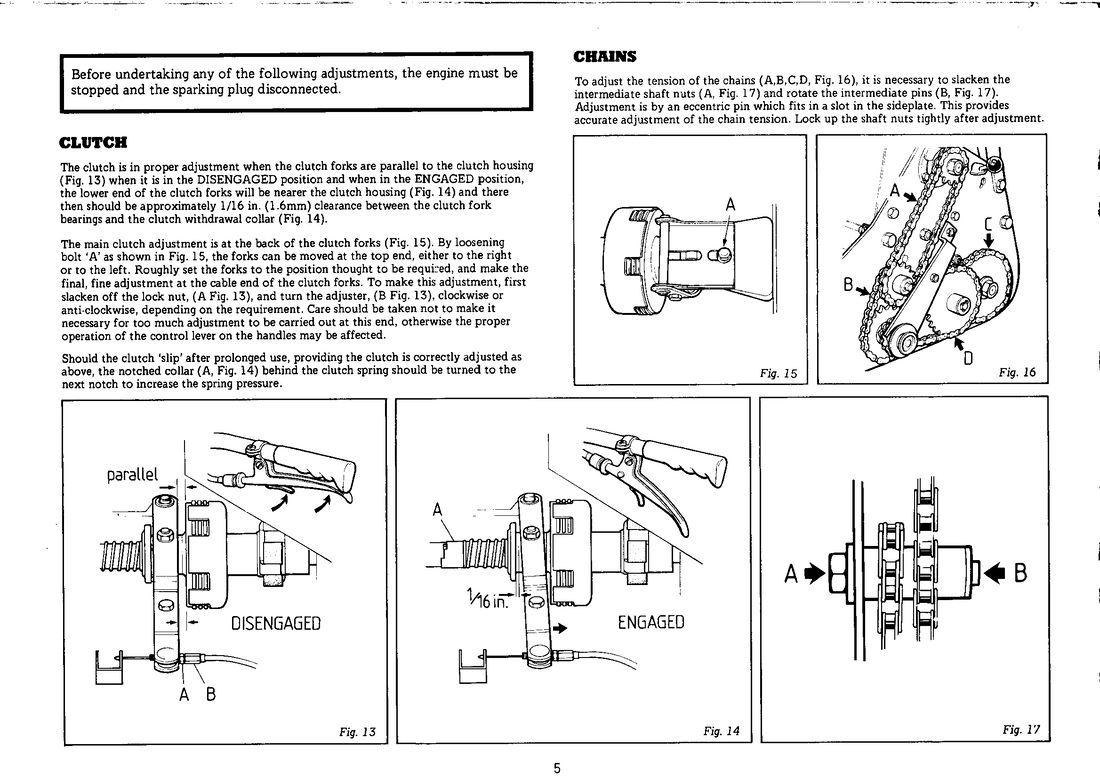

Clutch

Clutch adjustments and lubrication are shown in the Atco instructions below. However, Shane includes an adjustable nipple on the end of the clutch cable (see photo below). This is a distinct improvement, adding a further adjustment capability but also making is cheaper to replace the cable with an off-the-shelf cable rather than a special cable with soldered nipple.

Lifan Engine Manual

Click below to download the Lifan engine manual

Click below to download the Lifan engine manual

| lf120-lf200-lf212-manual.pdf |

Spare parts

Some parts on the Brilliant mower are specially made for the mower. These include the cutting cylinder and gears. I would always go to Shane first for parts or advice - he keeps a stock of spares and has in-depth knowledge of these mowers. Our experience with some mower engineers who purport to have knowledge of cylinder mowers has not always been good.

NOTE. The Grass Delivery plate only applies to Atco Reconditioned mowers. The Brilliant Mower has an air deflector which doesn't need to be adjusted.

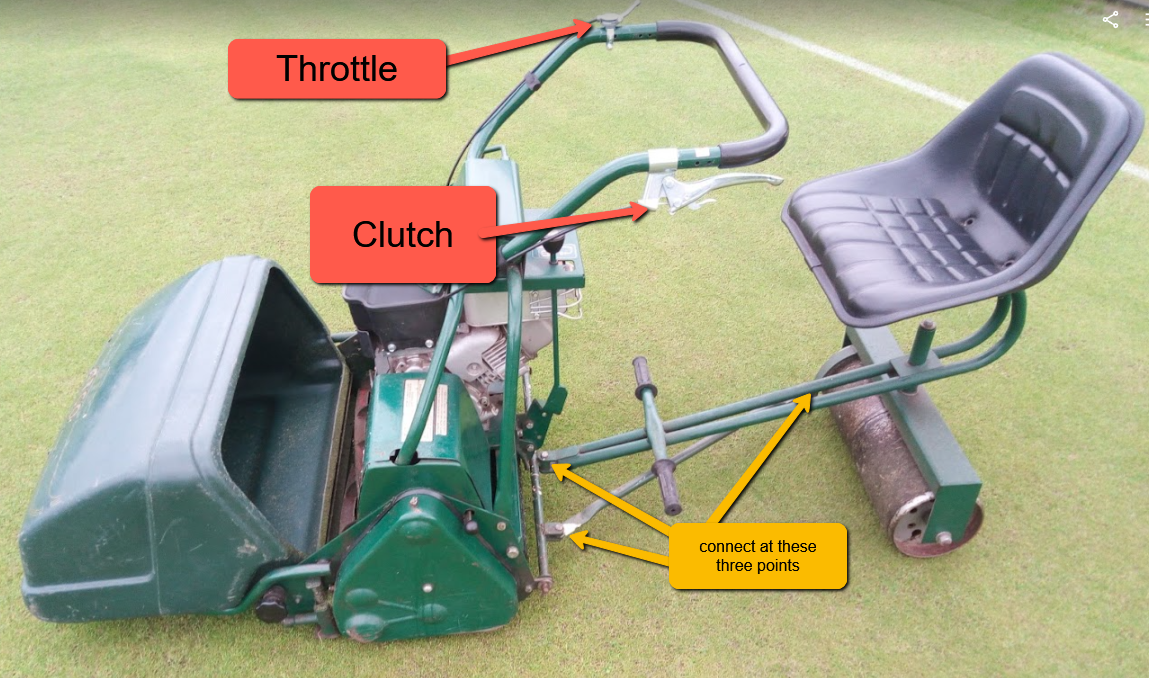

Assembly of trailing seat

If the trailing seat has been sent on a pallet, you will need to connect the at the three points shown.

The clutch, throttle and connection points are the same for Atco mowers and the Brilliant mower.

If the trailing seat has been sent on a pallet, you will need to connect the at the three points shown.

The clutch, throttle and connection points are the same for Atco mowers and the Brilliant mower.